Our planning is integrated now, which is very gratifying. Compared to most other companies we're way ahead in terms of the structured way we are interlinking the entire process – from strategic planning, to sales, to production planning.

This website will offer limited functionality in this browser. We only support the recent versions of major browsers like Chrome, Firefox, Safari, and Edge.

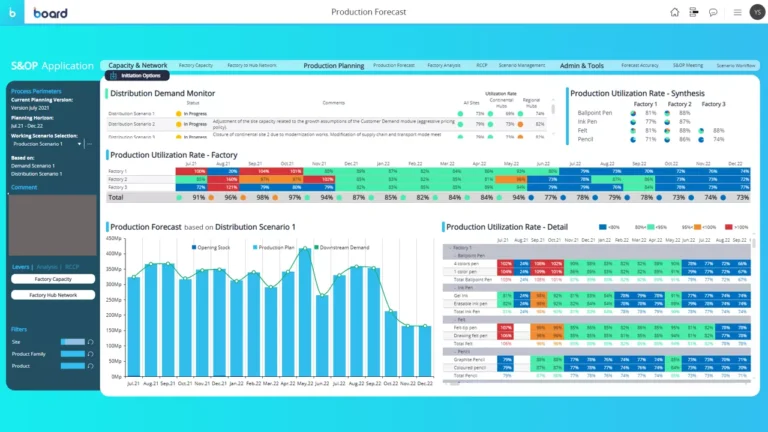

Test your effective capacity and maximize your operational efficiency

Successfully deal with volatility in customer demand using Board to create complete transparency of key resource availability and test operational capacity, boosting process efficiency.

Board’s Intelligent Planning Platform enables companies to effectively conduct Rough-Cut Capacity Planning (RCCP) based on a unified, transparent view of business data.

Acknowledge the master production schedule in terms of product volumes to be fulfilled and relative requirements for key resources such as workforce and capital

Calculate a rough estimate of the needs in terms of critical resources such as headcount, number of shifts, plants, machines, and utilization rate

Compare the estimated need for key resources against demonstrated capacity from actual performance data and validate or adjust the master production schedule accordingly

Accomplish rough capacity planning and periodical re-planning cycles to detect, on time, specific cases which deviate from the norm and avoid critical issues in terms of bottlenecks and over-saturation

Take advantage of native collaborative workflow capabilities, guaranteeing continuous collaboration among the supply chain and HR departments

Our planning is integrated now, which is very gratifying. Compared to most other companies we're way ahead in terms of the structured way we are interlinking the entire process – from strategic planning, to sales, to production planning.