Supply Planning that balances service, cost, and resilience – on one Enterprise Planning Platform

Board’s Supply Planning software helps organizations optimize procurement, inventory, and production plans. With segmentation, constraint-based logic, and scenario planning, you can balance service, cost, and margin in one connected process.

Board is recognized by analysts for continuous, finance-aligned planning.

Gartner highlights scenario agility and ISG cites best-in-class ROI and customer experience.

Board is included in the 2025 Gartner® Magic Quadrant™ for Supply Chain Planning Solutions.

Continuous, finance-aligned supply planning built for resilience.

Set the right inventory targets

Define dynamic safety stock and service policies by product, channel, or region. Board’s multi-echelon planning ensures the right stock is in the right place.

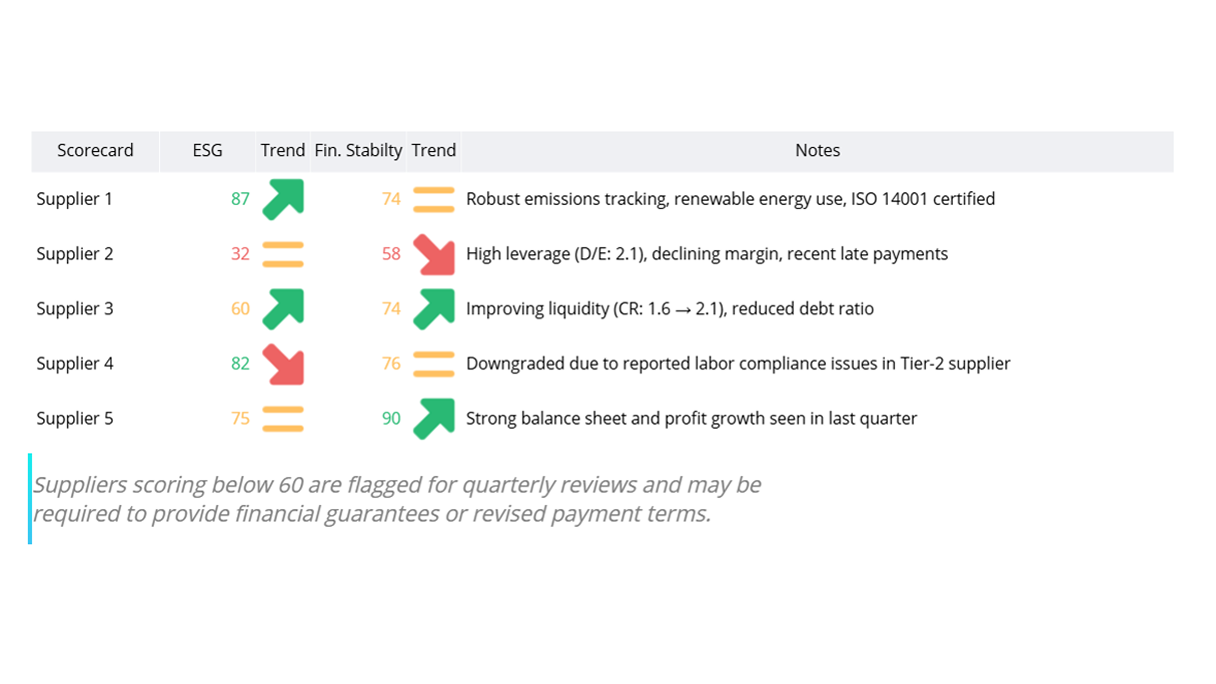

Create executable, constraint-aware plans

Generate time-phased supply and distribution plans that reflect lead times, sourcing rules, and supplier capacity – always realistic, always executable.

Plan with scenarios, not spreadsheets

Simulate supplier risk, network redesign, or policy changes with built-in scenario planning. Compare outcomes instantly across service, cost, and margin.

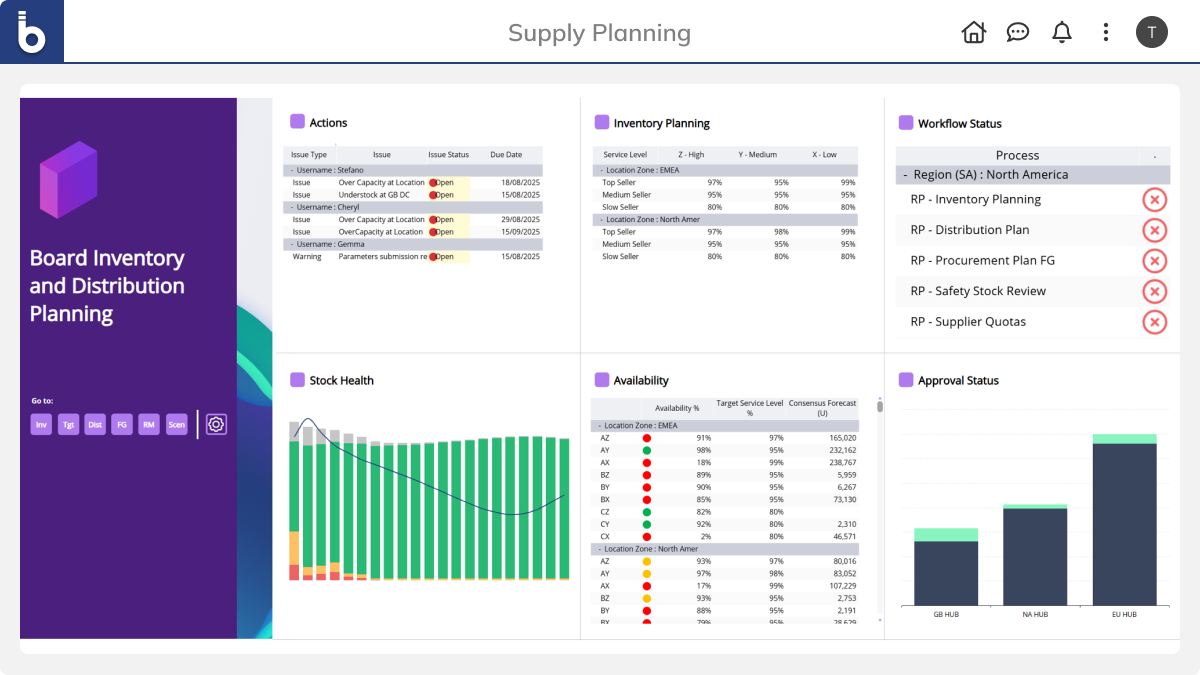

Collaborate across the supply chain

Unite procurement, logistics, and finance teams around one shared plan. Secure, role-based workflows keep everyone aligned to the same numbers.

Automate the routine, focus on value

Exception-based workflows flag shortages, excess stock, or parameter conflicts – so planners spend less time firefighting and more time optimizing.

Trusted by leading enterprises.

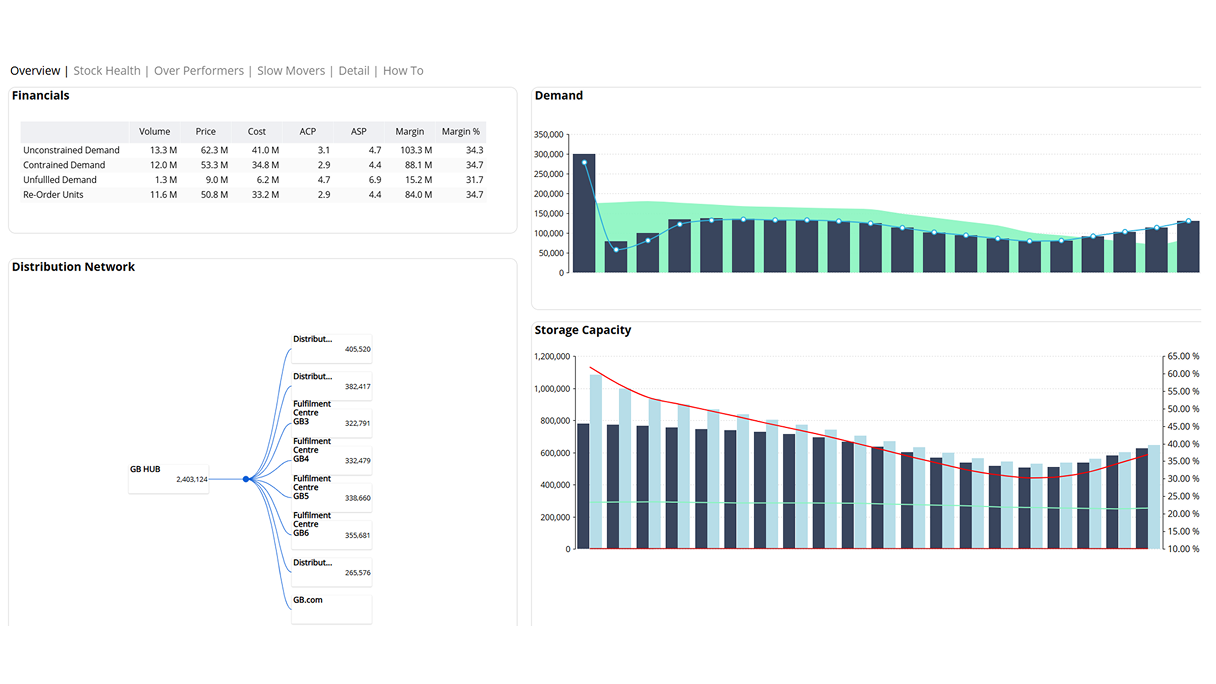

End-to-end supply planning, connected to demand and finance.

Inventory & Distribution Planning

Balance service and capital with dynamic inventory

Optimize stock, replenishment, and distribution across multi-tier network

Supply & Procurement Planning

Optimal supply plans aligned to cost and capacity

Align purchase orders and supply policies to supplier lead times and sourcing rules.

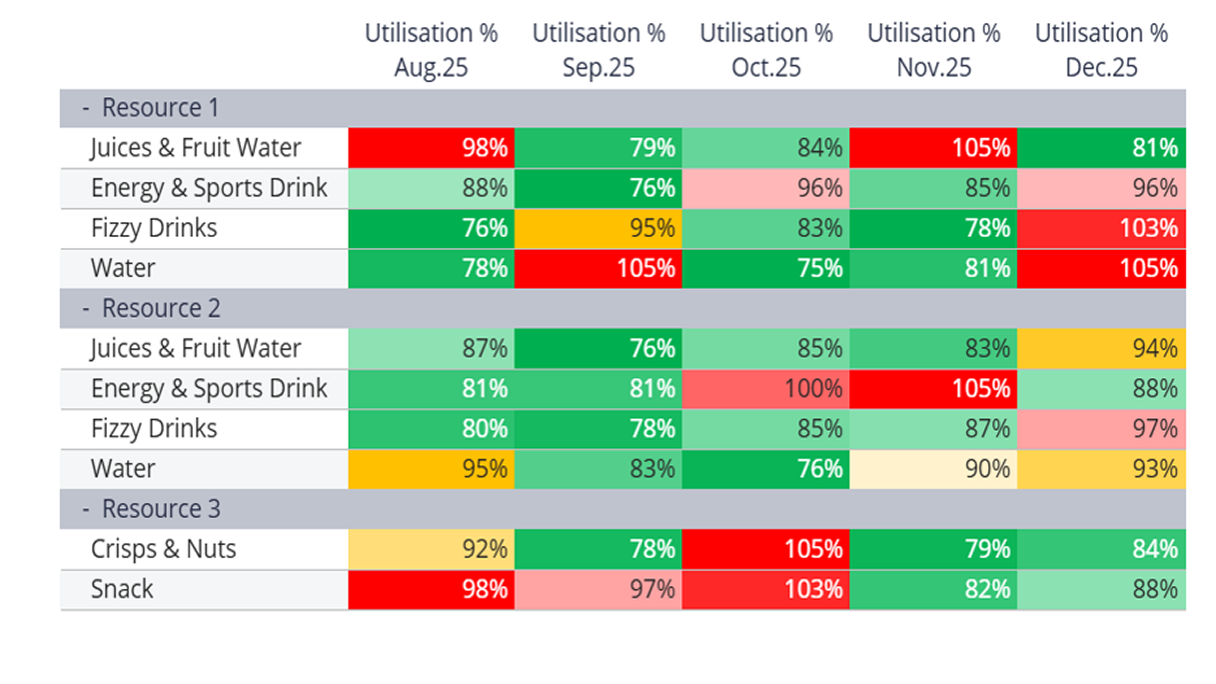

Rough-Cut Capacity Planning

Spot constraints early, deliver feasible plans

Validate feasibility of plans against real capacity and logistics constraints.

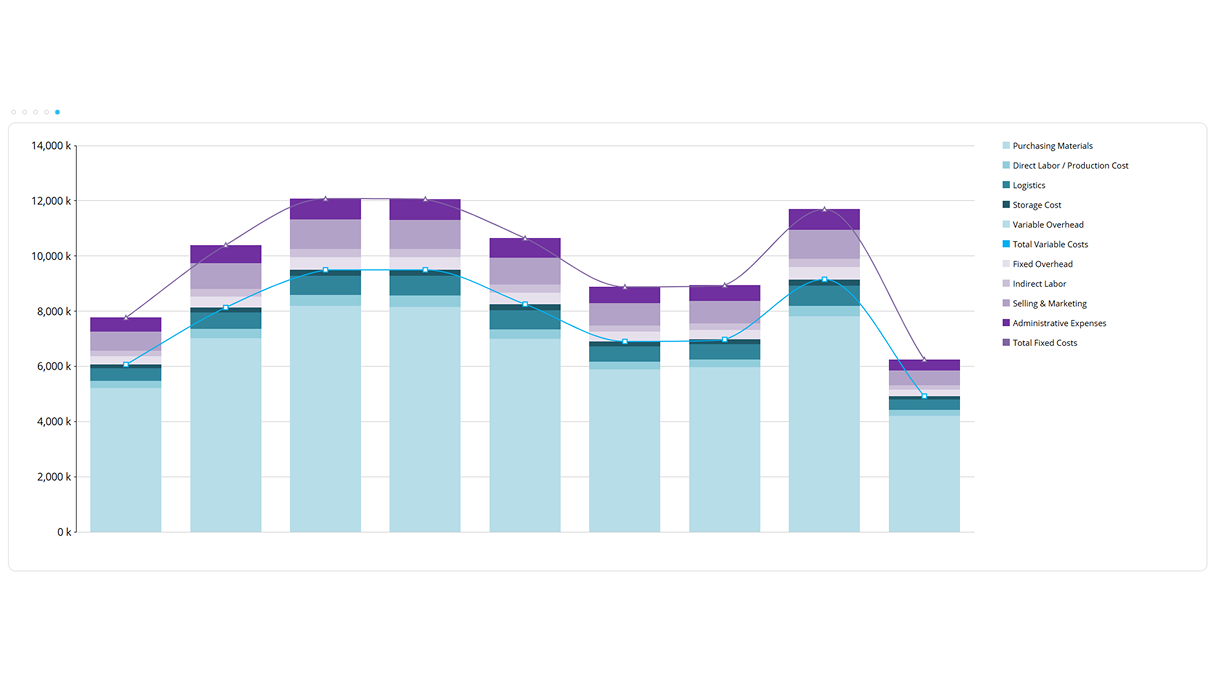

Executive Supply Review

Executive-ready plans that align supply and finance

Deliver one reconciled, financially aligned plan for leadership approval.

Built for a continuous planning experience.

All our planning solutions converge on the Board Enterprise Planning Platform to help you make confident, aligned decisions. They transform your planning process by accelerating time to value, driving cost effectiveness, and reducing risk.